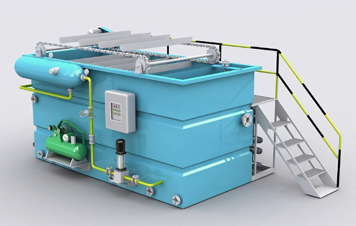

The Inorganic Membrane Pressurized Separation Integrated Water Reuse System combines coagulation–pre-sedimentation, pressurized inorganic membrane filtration, and UV disinfection into a single modular unit. The system reliably retains micro-flocs and suspended solids regardless of settling characteristics, then delivers deep disinfection to produce clear, stable effluent ready for reuse.

Coagulation – Pre-Sedimentation – Inorganic Membrane Filtration – UV Disinfection – Effluent

Pressurized inorganic membranes complete rapid, continuous filtration—unlike slow gravity settling—boosting throughput, adapting to variable flow and quality, and reducing footprint and civil works.

| Capacity (m³/d) | Dimensions (L×W×H mm) |

|---|---|

| 100 | 5000×2500×2200 |

| 200 | 5000×2500×2500 |

| 300 | 5000×3000×2640 |

| 400 | 6000×3000×3000 |

| 500 | 6500×3000×3000 |

| 600 | 7000×3000×3000 |

The AOP-FlotexT™ system injects ozone into an Fe*-catalyzed advanced oxidation process, generating abundant ·OH radicals that non-selectively break down refractory organics. Aromatic hydrocarbons, dyes, and pharmaceutical residues are cleaved and mineralized into smaller, biodegradable molecules, effectively reducing COD. In the flotation zone, a specialized microporous diffuser releases microbubbles, synchronizing oxidation and flotation: oxidation products and flocculants attach to bubbles, rise as scum, and are removed by a mechanical scraper. This integrated approach achieves 50%–80% COD removal for wastewaters that challenge conventional biological treatments.

| Model | Flow Rate (m³/h) | Main Motor (kW) | Aeration Motor (kW) | Scraper Motor (kW) | Total Power (kW) |

|---|---|---|---|---|---|

| FY-5T | 3–5 | 1.1 | 0.55 | 0.37 | 2.02 |

| FY-10T | 5–10 | 1.5 | 0.55 | 0.37 | 2.62 |

| FY-20T | 15–20 | 2.2 | 0.75 | 0.37 | 3.32 |

| FY-50T | 40–50 | 7.5 | 1.5 | 0.37 | 9.37 |

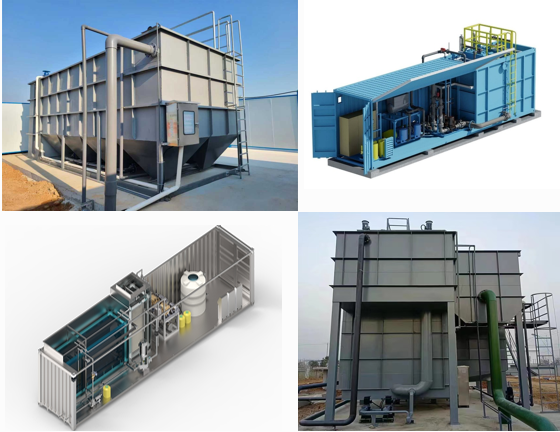

Modular Integrated Wastewater Treatment Equipment is a compact wastewater treatment system that integrates multiple units of the wastewater treatment process, such as pre-treatment, biological treatment, sedimentation, filtration, and disinfection, into one or more modules. Through rational design and combination, these modules work synergistically to achieve efficient wastewater treatment. Its core features include flexible configuration, rapid deployment, and adaptability to decentralized treatment needs.

| Comparison Item | Traditional Wastewater Treatment Plants | Modular Integrated Equipment |

|---|---|---|

| Construction Period | 6–12 months | 1–4 weeks (factory prefabrication + on-site installation) |

| Footprint | Large (requires structures) | Small (compact design, saves 50%–80% space) |

| Adaptability to Water Quality Changes | Difficult to modify | Quickly adjust processes by adding or removing modules |

| Mobility | Fixed, non-movable | Supports relocation and reuse |

The Industrial Park Sewage Advanced Treatment and Reuse Equipment achieves efficient purification and resource reuse of sewage through a two-stage membrane separation technology (Ultrafiltration Membrane System + Reverse Osmosis Membrane System). The ultrafiltration membrane screens and retains suspended solids, colloids, and macromolecular organic substances, serving as a pretreatment unit to ensure water quality stability. The reverse osmosis membrane, based on the selective permeability principle of semi-permeable membranes, removes dissolved salts, small molecular organic substances, and heavy metal ions (desalination rate >98%).

This system is suitable for advanced desalination of sewage and the preparation of reclaimed water, applicable to electronic electroplating wastewater, chemical high-salt wastewater, and pharmaceutical organic wastewater. It can be reused for cooling circulation water, boiler feed, or production processes, helping industrial parks achieve near-zero discharge of sewage and a circular economy of water resources while meeting stringent environmental requirements.